Building a DIY aquarium is fun and keeps many challenges in itself. Here is a complete procedure with a material list required for building a DIY fish tank.

Content Table

In the following, you will learn how to DIY an aquarium while keeping a 60-gallon fish tank example, without a brace. You will also find other information about using epoxy resin and other materials used for it.

Can It Use Epoxy Resin to DIY a Fish Tank

Epoxy resin is popular nowadays. You can find its use in several DIY products, i.e., jewelry, decoration items, etc. However, you can’t use it for the DIY fish tank for many reasons. Some of the reasons that make it inappropriate are the following.

Aqua Pets Safety

Epoxy resin usually contains chemicals. It is dangerous to use it for a DIY fish tank. In case of any chemical leaching, fish can face severe impact. Although some available epoxy resins claim that they are 100% organic, it is recommended that don’t use them.

Strength

Glass and other materials are far more sturdy in the same thickness as epoxy resin. Therefore, it is better to use other materials instead of epoxy resin.

Transparency

Epoxy resin makes the view dull and blurry. While aquariums are kept for watching the aqua pet playing around. Therefore, use other materials instead of it is a better choice.

Some Suggested Materials

There are some other materials that you can use for a DIY fish tank.

- Glass

Glass is widely used among aquarium enthusiasts. It is great in transparency, strength, safety, and maintenance aspects.

- Fiberglass

It is used for large DIY fish tanks. However, it requires some proper sealant, i.e., epoxy resin, for proper boding.

- Acrylic/Plexiglass

Plexiglass is more lightweight than glass. However, some aspects downgrade it from glass, i.e., scratches easily, and a thick panel is required.

Material Can Be Used to Join the Glasses of an Aquarium

Several glass-bonding materials help in joining the DIY glass aquarium panels. Some of them are in the following.

- Aquarium-grade silicone sealants

- Glass Adhesives

- Acrylic cement

However, aquarium-grade silicone sealant, i.e., GE silicone II, is inexpensive, commonly available, and suitable for aqua pets.

Other Materials

Besides the silicone glue, some other materials are also required to DIY a fish tank. Here is a list of the materials.

- Tempered Glass Panels

- Glass cutter (optional)

- Sandpaper (optional)

- Masking tape

- Duct tape

- GE Silicon II glue

- Silicon glue gun

- Scissor

- 70% Isopropyl Alcohol

- Razor Blade

- Gloves

- Removable Ink Marker

- Tissue paper

- Paper

How to DIY an Aquarium

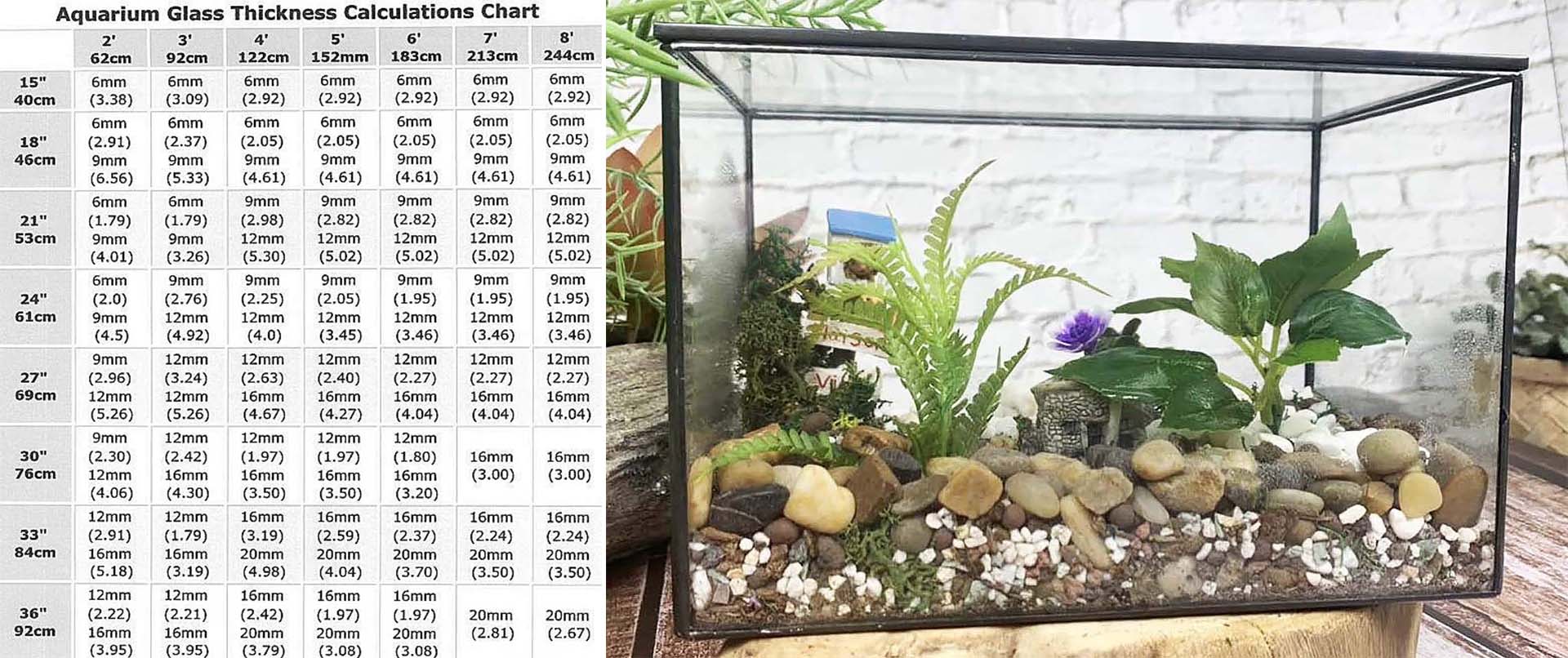

Follow this procedure to have a leakage-proof and well-finished aquarium. Taking a 60-gallon tank as an example to explain the procedure. If you are desiring any other dimension, then cut a glass with proper thickness according to the desired dimension. You can find the safe thickness for the glass from the chart.

Glass Cutting

If you have experience of glass cutting, then go for it. Otherwise, it’s suitable to visit some professional for this task.

The suitable dimensions for a 60-gallon tank are to have 5 tempered glass panels 48 inches in length, 12 inches in width, and 24 inches in height.

After cutting, smooth the sharp edges. It’ll help in leak-proof bonding and other dangers.

Mask the Glass Panels

Once you have proper glass panels, mask the glass panels’ sides with mask tape. Leave the space according to the panel thickness. Masking tape helps to have a smooth and clean operation.

Attach the masking tape in such an order that the tape peels from the sides with ease.

Label the Panels

Label the sides of the glass panels, i.e., front, back, left, right, and peel off the order of masking tape. This labeling will help you join and finish your DIY project.

Joining the Glass Panels

Spread a piece of paper on a smooth and horizontal surface and place all the glass panels in the right arrangement. Cut about 16 pieces of a 5-inch length of duct tape and hang them near your surface. Clean the sides with 70% isopropyl alcohol to remove all debris and oil. These things will cause loose bonding.

Cut the GE silicon II glue nose at a 45-degree angle. Cut the cap according to your desired bead width. Use the opener needle that is present on the glue gun.

After setting up everything, place the glue cane in the gun and apply it on both surfaces. After the vertical glue bond, secure them with cut duct tap pieces. Apply the glue on the rest of the sides and secure them with duct tape to both the base and side panels.

Once you have finished vertical bonding, then apply one or two times glue from inside to make them leakproof.

Applying EVA Foam at the Bottom

Take an EVA foam according to the bottom plate size and apply it at the bottom. It will increase the portability and strength at the bottom.

Cleaning

Once you have completed the task, remove the masking tape from the sides. Use a razor blade to remove extra silicon sealant beads from the surface.

Once you have done this procedure, leave it for 24 to 48 hours for sturdy bonding.

After the Fish Tank Is Done

Once you have finished your DIY tank, do a water test. Remove the duct tape from the side panels, fill the aquarium with water, and check the leakage. If everything is fine, then you can go with it.

Apply all accessories over your new tank, i.e., water, filter, pump, aquarium decors, etc. Maintain a proper living environment for your fish and free them in your newly set aquarium.

Summary

Take five glass panels of the desired dimension with the required items. Gather the things, mask the panels, clean the edges, apply silicon glue on the sides, glue the EVA foam on the bottom, finish the surface, and leave it for 24 to 48 hours. It is the simple and short answer to how to DIY an aquarium.

In this article, I’ve left the choice to place the side panels inward or on the edges. Whatever arrangement you adopt is fine. You can also go with the combination of both arrangements.

Leave a comment